Picture frame production involves several key steps, including the selection of materials, cutting, assembling, and finishing the frames. Here's an overview of the typical process:

- Material Selection

- Wood: One of the most common materials for picture frames. Different types of wood, like pine, oak, and mahogany, are chosen based on aesthetics, durability, and cost.

- Metal: Frames can also be made from aluminum or steel for a more modern or industrial look. These materials are more durable and often used for frames with a sleek design.

- Plastic: Some picture frames are made from various plastics, which are cost-effective and lightweight.

- Glass and Acrylic: These materials are used for the front face of the frame, protecting the picture. Acrylic is often used in place of glass for its lightweight and shatterproof properties.

2. Cutting and Shaping

- Frame Molding: The raw material (wood, metal, or plastic) is cut into long strips called moldings. These moldings are typically available in various shapes, such as flat, ornate, or rounded.

- Cutting the Frame: The moldings are cut to the specific size needed for the frame. The cuts are typically made at 45-degree angles for mitre joints, where the ends of the frame pieces meet.

- Joining: The frame pieces are then joined at the corners. Common methods include using glue, nails, screws, or specialized frame joiners. In the case of wooden frames, miter joints are often reinforced with metal corner brackets or dovetail joints.

- Assembly

- Assembling the Frame: After cutting, the four pieces of the frame are glued and nailed or secured together. In professional production, corner clamps are used to ensure the frame is square and stable.

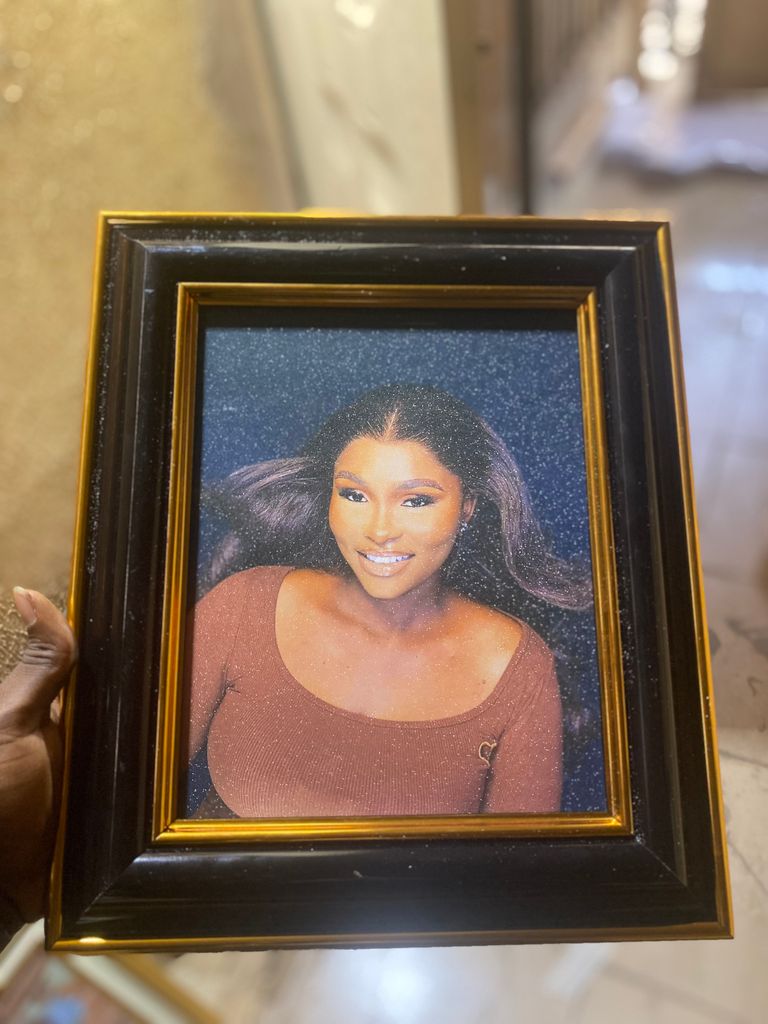

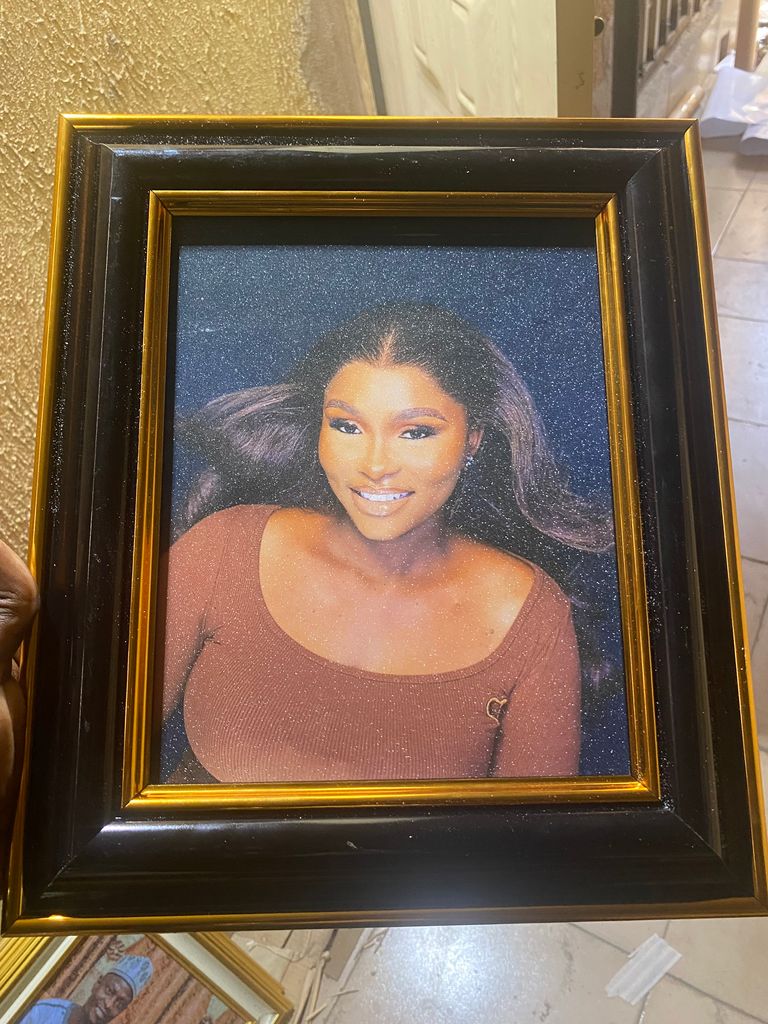

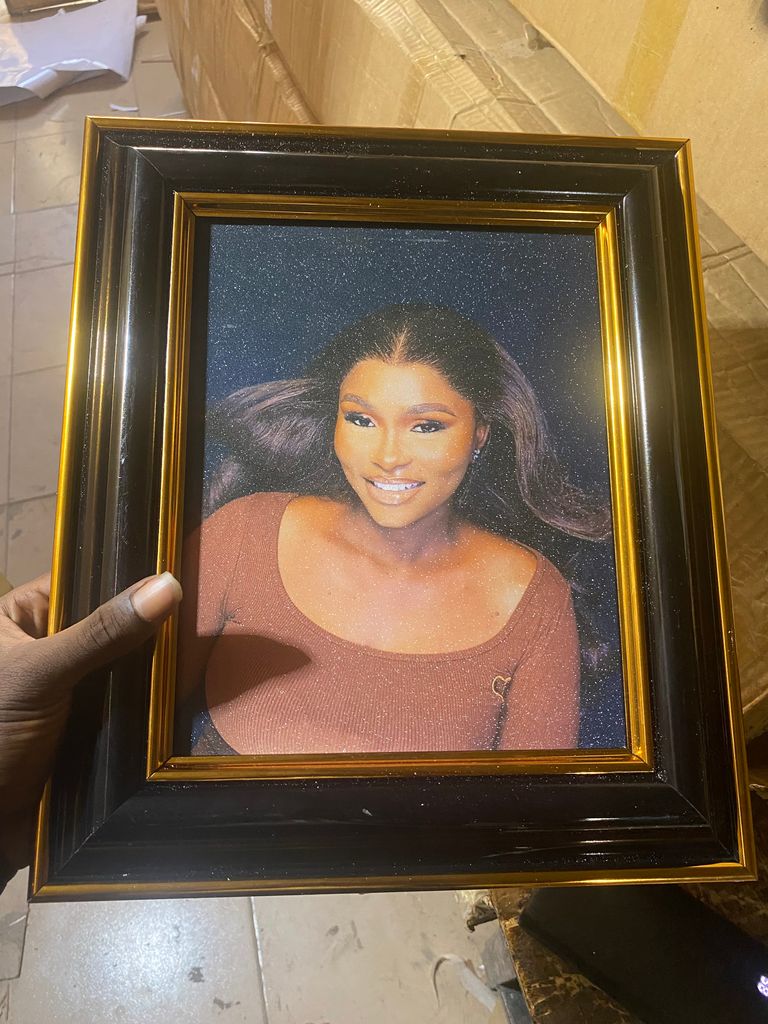

- Mounting the Picture: A backboard is cut to fit the size of the frame, and the picture is placed in the frame along with any protective glazing (glass or acrylic). The frame is then secured using small clips or fasteners.

- Finishing

- Sanding: If the frame is wooden, it will be sanded to smooth any rough edges and ensure a clean, finished surface.

- Painting or Staining: Frames may be painted, stained, or varnished to enhance their aesthetic appeal. Wood frames are often stained to bring out the natural grain, while metal frames are painted or anodized.

- Polishing: After the frame is painted or stained, it may be polished to give it a shiny, smooth finish.

- Quality Control

- Each frame is inspected for defects, such as cracks in the wood, imperfections in the finish, or misaligned corners.

- The glass/acrylic front is also checked for clarity, scratches, and other imperfections.

- Packaging and Shipping

- Once the frames are completed, they are carefully packaged to prevent damage during shipping. The finished products are then ready for distribution to retailers or customers.

Thank you for stopping by my post today, I hope you enjoy my content please drop a comment below and state how useful this content was to you. Thank you for support

Congratulations, your post has been upvoted by @dsc-r2cornell, which is the curating account for @R2cornell's Discord Community.

Enhorabuena, su "post" ha sido "up-voted" por @dsc-r2cornell, que es la "cuenta curating" de la Comunidad de la Discordia de @R2cornell.